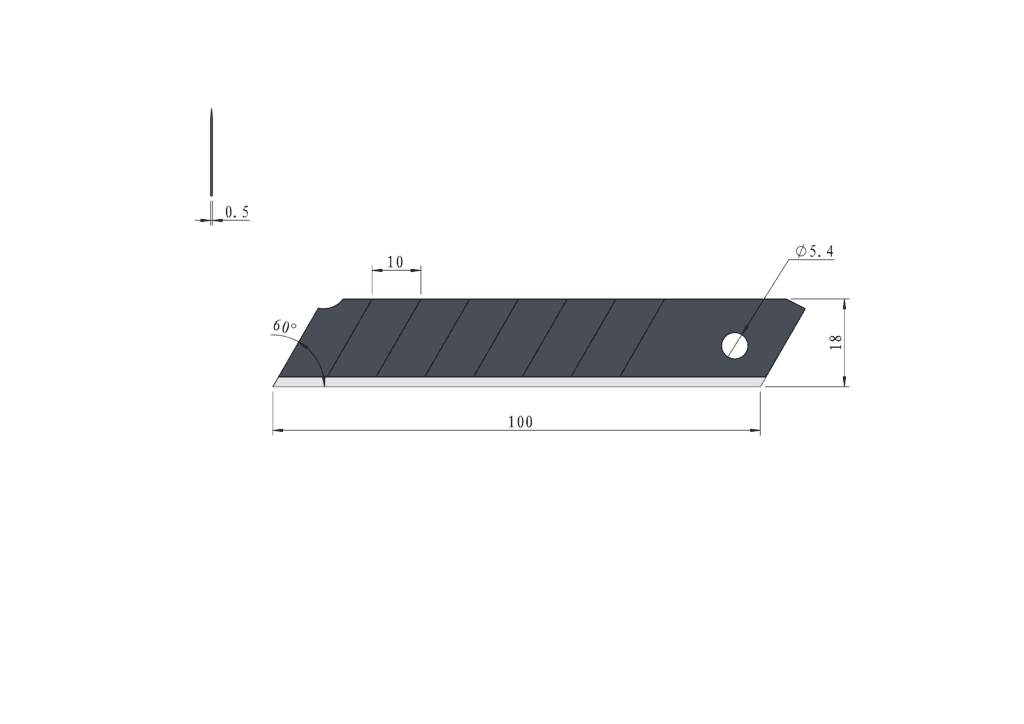

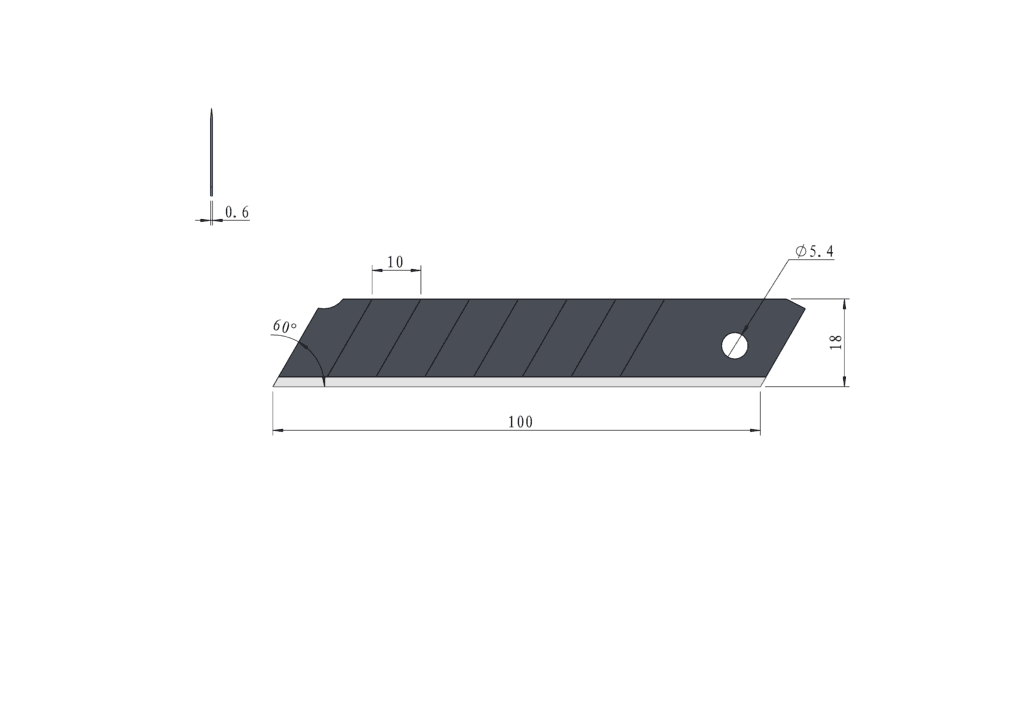

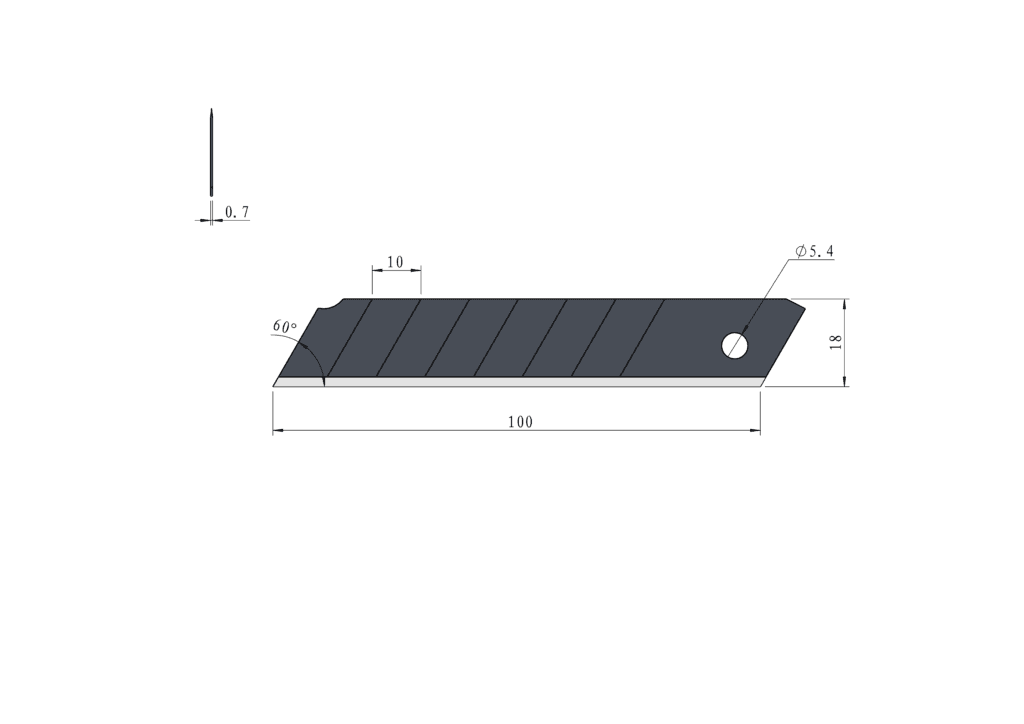

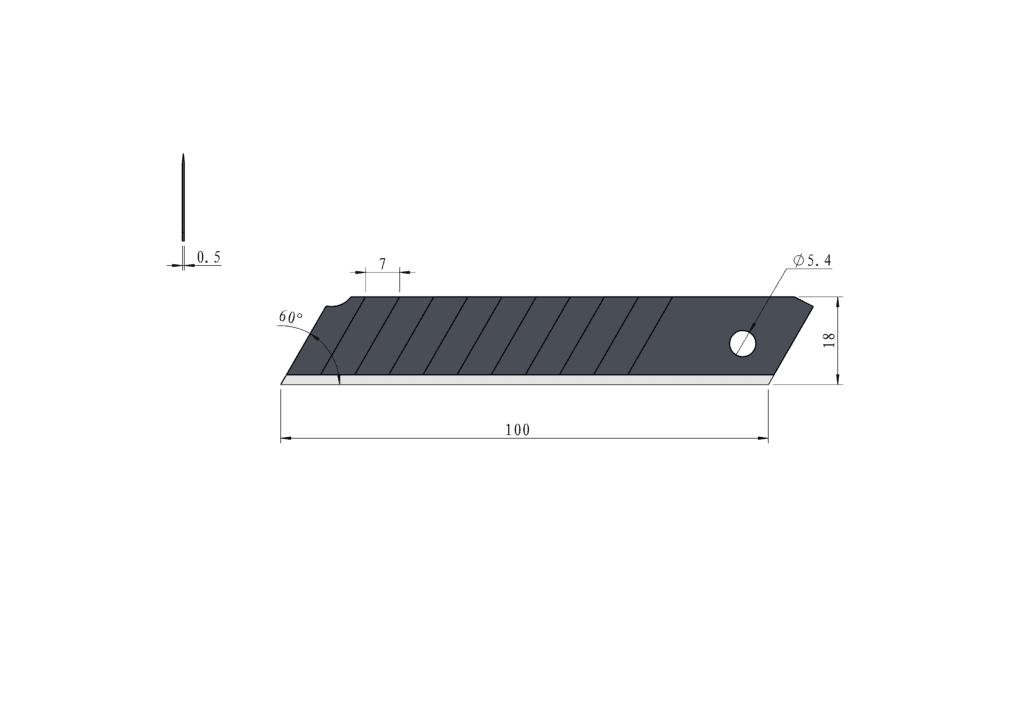

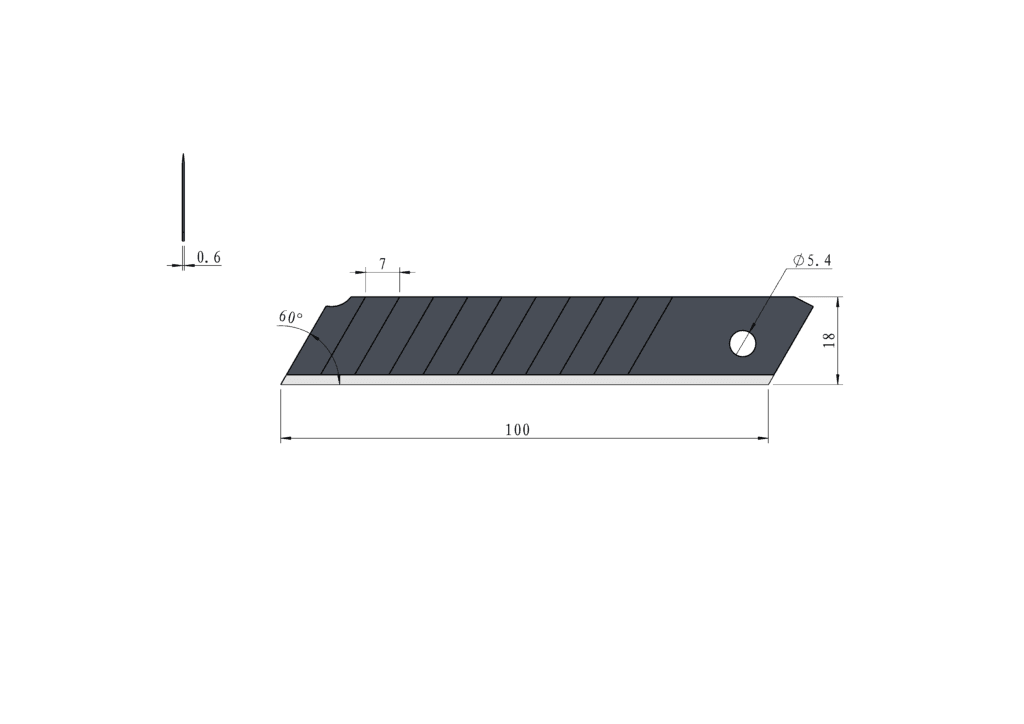

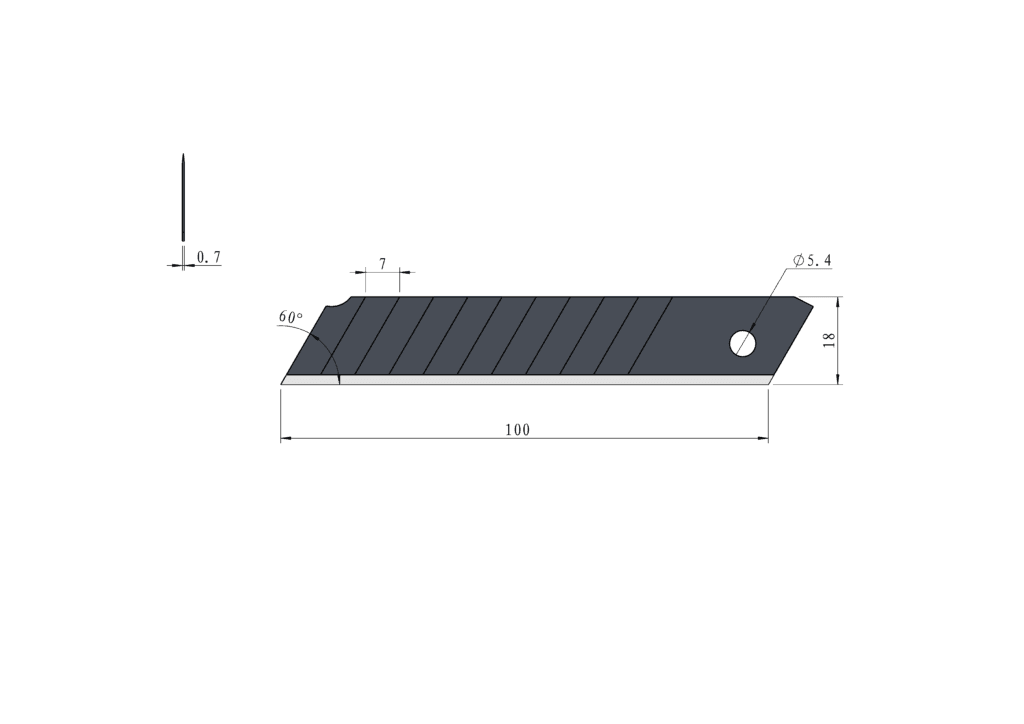

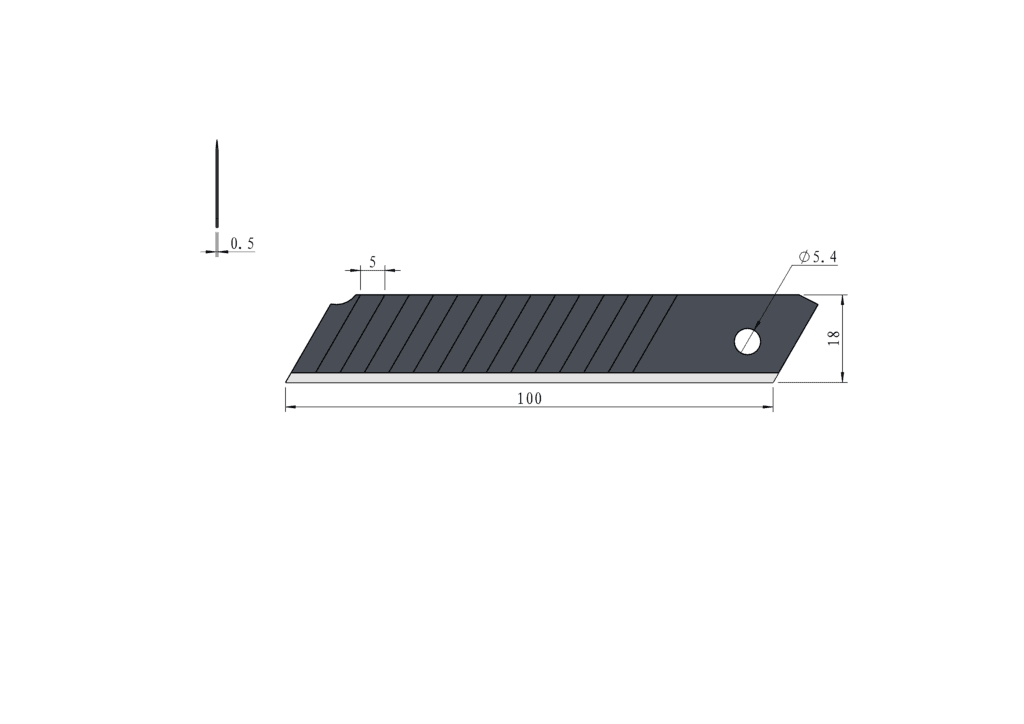

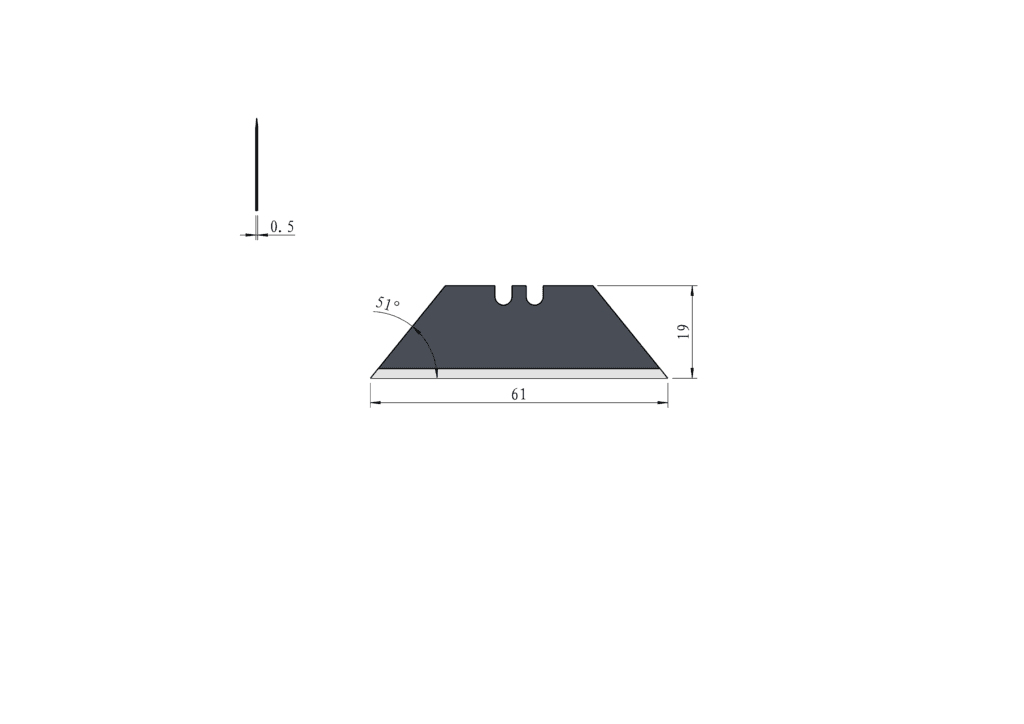

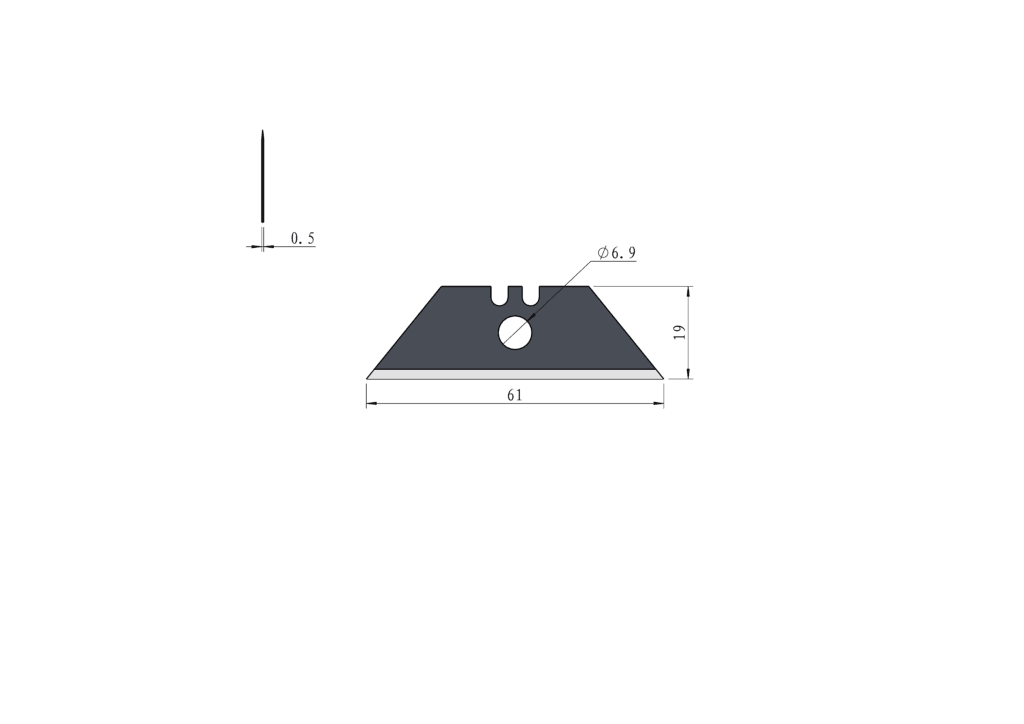

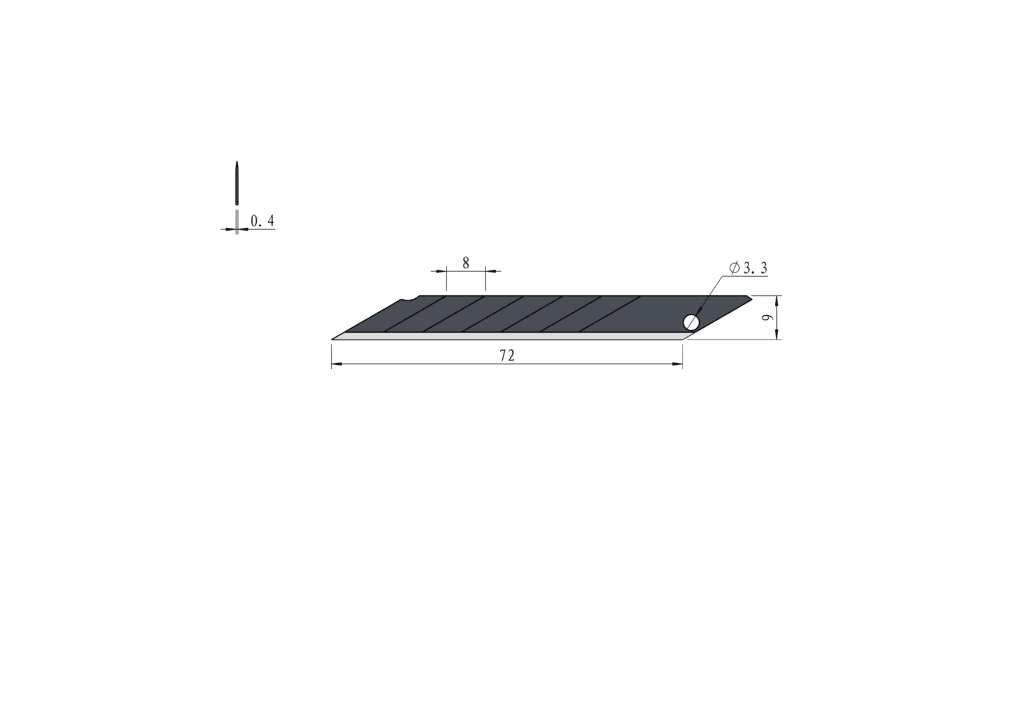

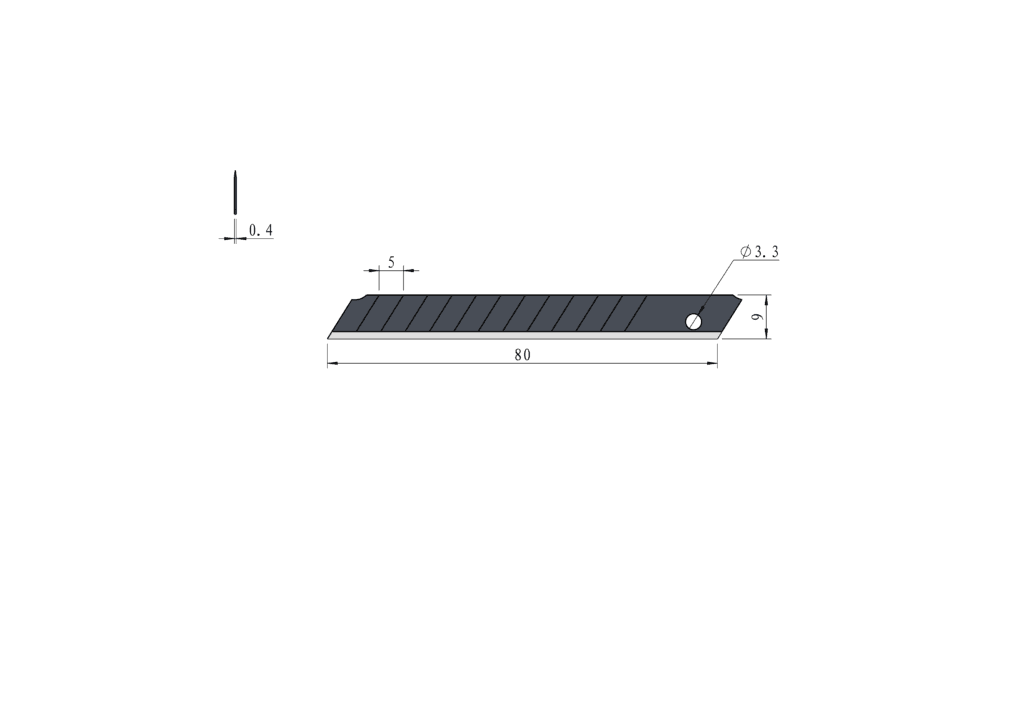

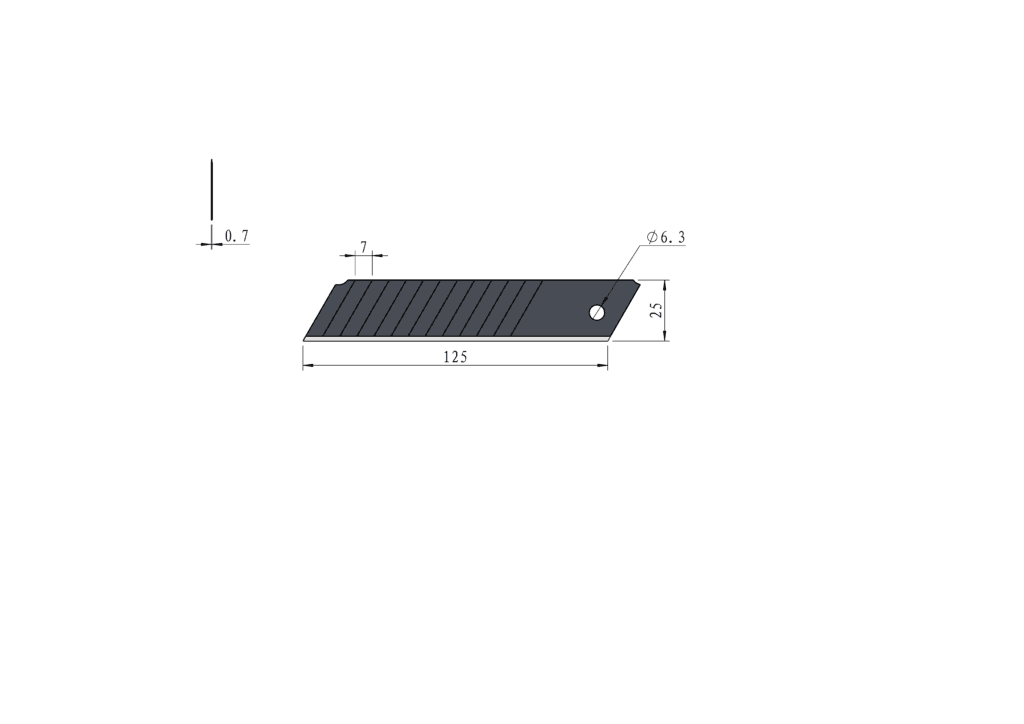

Illustrative Diagram of Our Company’s Standard Blade Products(with options for custom mold opening and production)

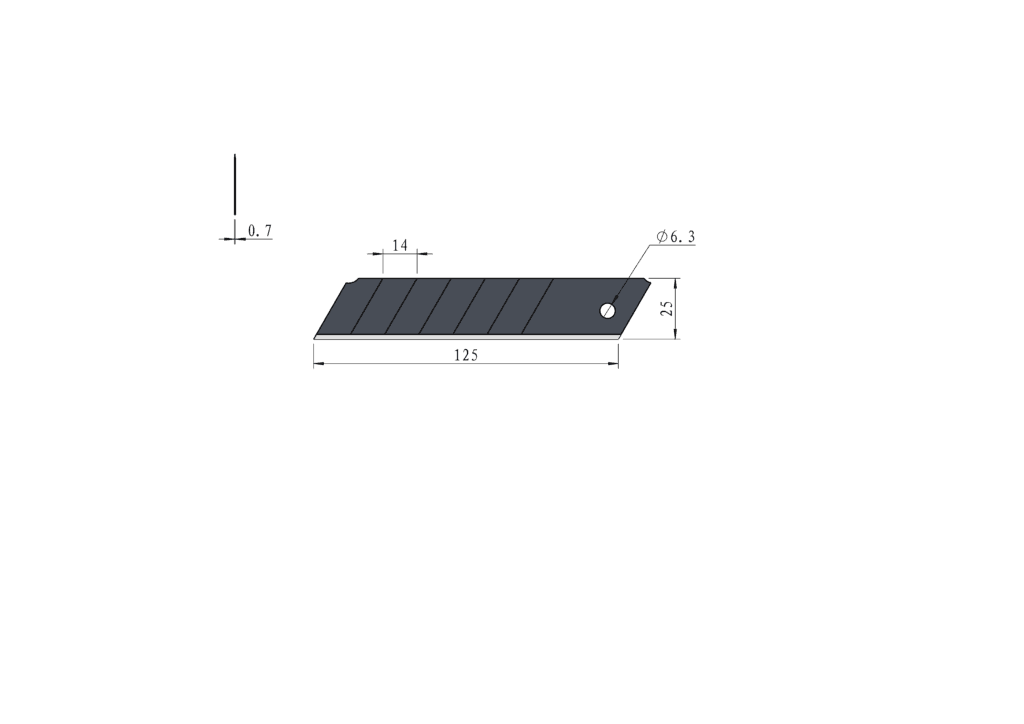

Common Specifications of Utility Knife Blades

Blade Width:

- 9mm: Suitable for delicate cutting tasks such as paper cutting and paper engraving.

- 18mm: The most common size, suitable for various general-purpose cutting tasks such as fabric trimming and wallpaper cutting.

- 22mm: Used by some brands or for special purposes.

- 25mm: Suitable for tasks requiring larger cutting areas, such as trimming large sheets of paper or plastic boards.

Blade Length:

- 80mm: Typically paired with 9mm wide blades.

- 100mm: Most commonly used with 18mm wide blades.

- 125mm: Typically paired with 25mm wide blades.

Common Models of Utility Knife Blades

Classification by Blade Segments:

- Different widths of blades have different numbers of segments. For example, a 9mm wide blade usually has 13 segments and can be broken 13 times; an 18mm wide blade usually has 8 segments and can be broken 8 times; a 25mm wide blade usually has 7 segments and can be broken 7 times.

Classification by Blade Material:

- SK5 or SK2 carbon tool steel: Offers excellent hardness and wear resistance, suitable for various cutting tasks.

- Other alloy steels: Such as SK4, also provide good cutting performance and durability.

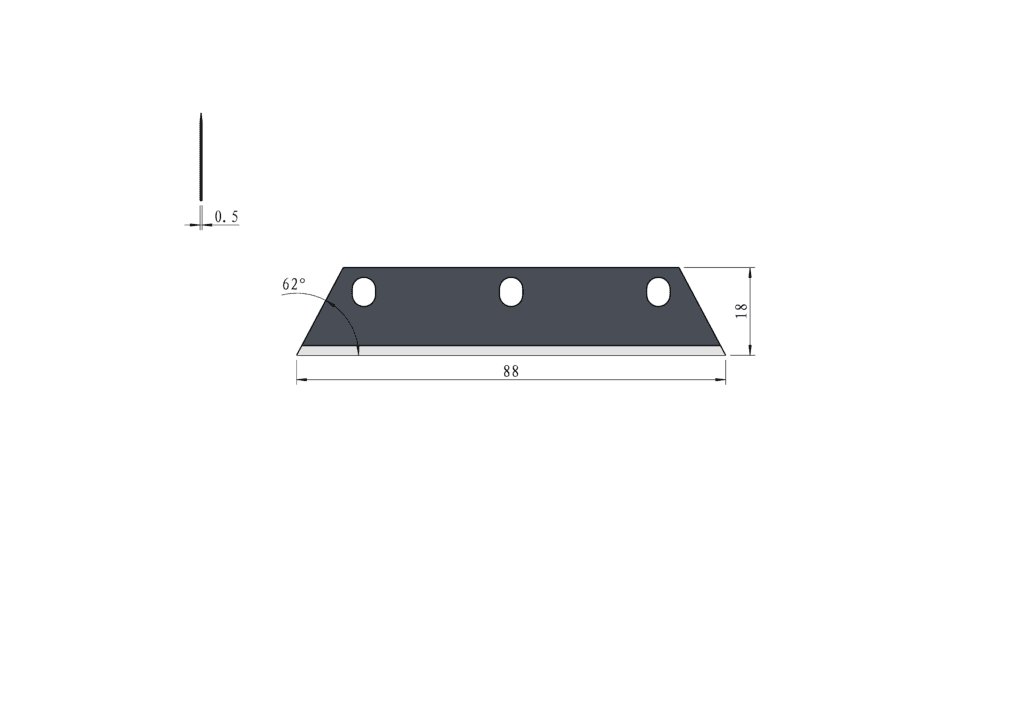

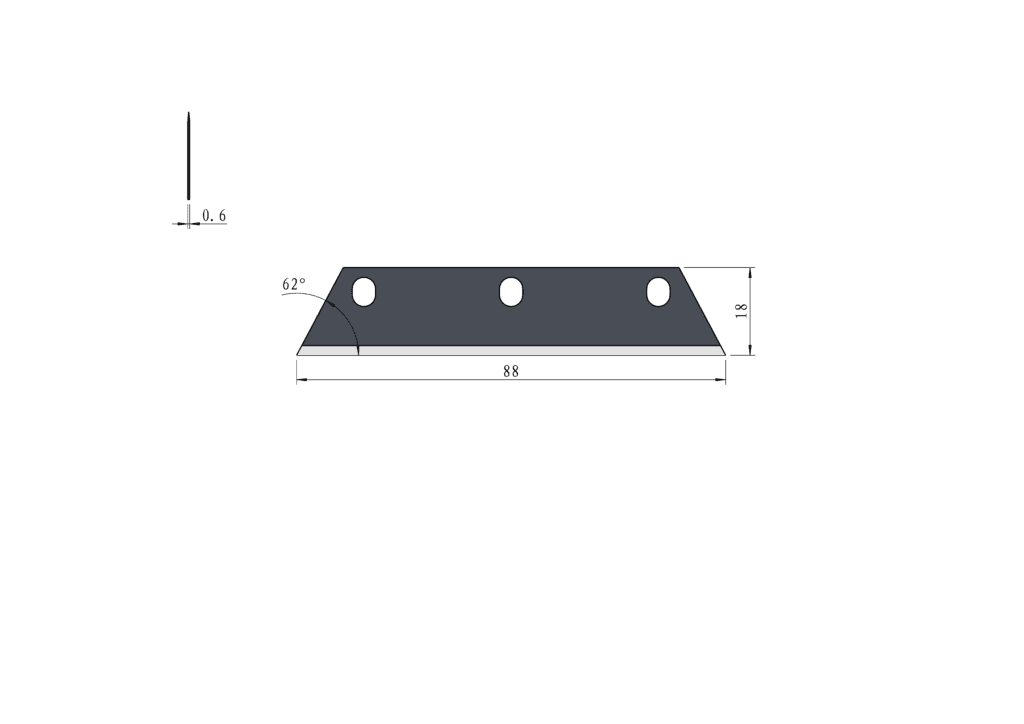

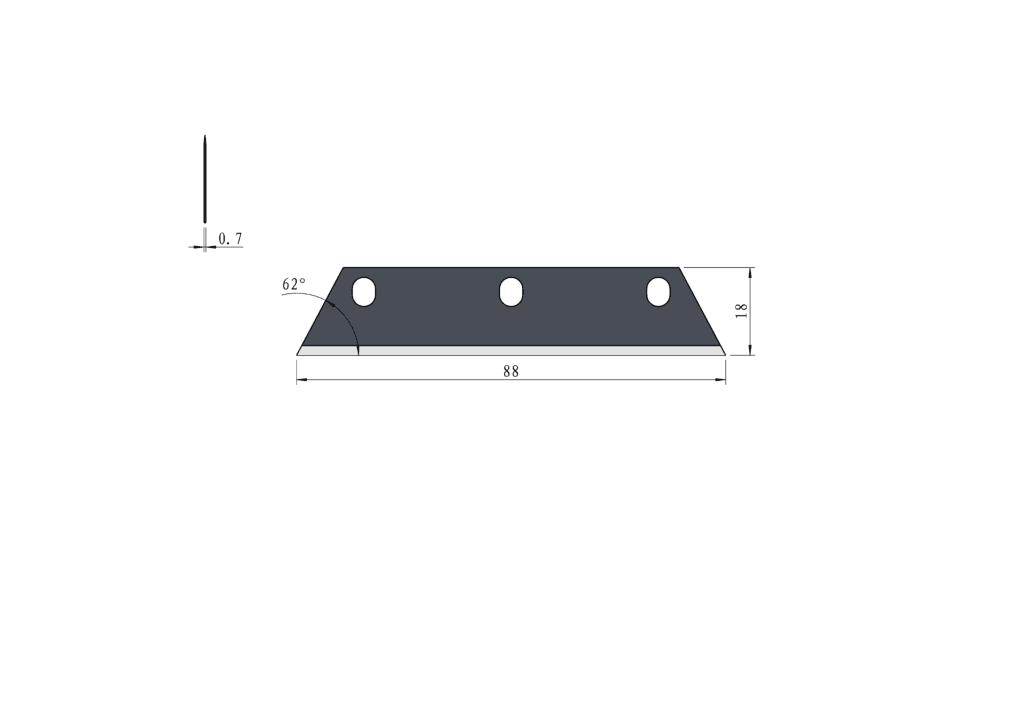

Classification by Blade Angle:

- Standard angle blades: Such as 60° oblique angle blades, suitable for most cutting tasks.

- Special angle blades: Such as 30° pointed angle blades, suitable for delicate cutting or engraving tasks.

Safety and Usage Tips

- Choose the Right Blade: Select the appropriate blade specification and model based on the specific cutting task and material.

- Proper Blade Installation: Ensure the blade is correctly installed on the utility knife holder to prevent blade loosening or detachment.

- Safe Operation: When using the utility knife, adhere to safety protocols to avoid blade injuries to fingers or damage to materials.

- Regular Blade Replacement: Replace dull or damaged blades promptly to ensure cutting effectiveness and safety.

Illustrative diagram of our company’s conventional blade products: