When it comes to cutting materials in various DIY projects, many people wonder about the effectiveness of using a utility knife to cut hardboard. Hardboard, also known as high-density fiberboard (HDF), is a versatile material used in furniture, cabinetry, and crafts. This article will explore whether you can cut hardboard with a utility knife, the techniques involved, and the best practices to ensure clean cuts. Additionally, we will delve into the role of utility knives in manufacturing and provide insights from a leading utility knife factory.

Understanding Hardboard

Before discussing cutting techniques, it’s essential to understand what hardboard is. Hardboard is made from wood fibers that are compressed under high pressure and temperature, resulting in a dense and durable sheet material. It is commonly used for:

– Furniture: As a backing material or for making cabinet doors.

– Craft Projects: For creating templates or art pieces.

– Flooring Underlayment: Providing a smooth surface for flooring installation.

Characteristics of Hardboard

– Thickness: Typically available in thicknesses ranging from 1/8 inch to 1/4 inch.

– Smooth Surface: One side is usually smooth, making it suitable for painting or veneering.

– Weight: Hardboard is relatively heavy compared to other materials like cardboard or plywood.

Can You Cut Hardboard with a Utility Knife?

Yes, you can cut hardboard with a utility knife, but there are specific techniques to follow for effective results. Using a utility knife to cut hardboard is most effective when dealing with thinner sheets (up to 1/8 inch thick). However, thicker sheets may require multiple passes or alternative cutting methods.

Techniques for Cutting Hardboard with a Utility Knife

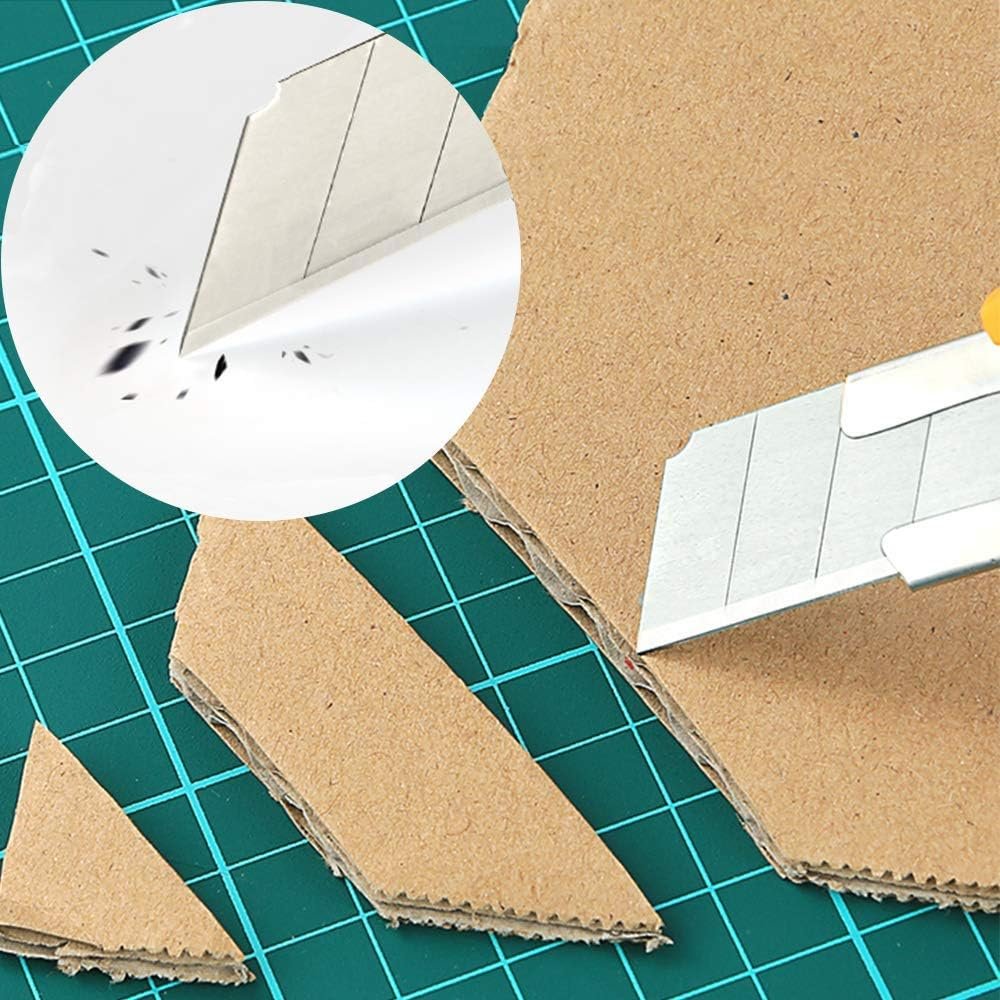

1. Scoring Method:

– Step 1: Place the hardboard on a stable surface with the smooth side facing up.

– Step 2: Use a straightedge or ruler to guide your cut. Align it along the desired cut line.

– Step 3: With your utility knife, score along the line using medium pressure. Make several passes over the same line until you penetrate through the surface layer.

– Step 4: Once you have scored deeply enough, place the hardboard over the edge of a table or workbench and apply pressure downward to snap along the scored line.

Scoring Method

2. Multiple Passes:

– For thicker hardboard (1/4 inch or more), you may need to make multiple passes with your utility knife. Each pass should deepen the score until you can snap it cleanly.

3. Using a Straightedge:

– Always use a straightedge when cutting to ensure clean lines and prevent jagged edges.

4. Safety Precautions:

– Always wear cut-resistant gloves when handling sharp tools like utility knives.

– Ensure your workspace is clear of obstructions that could interfere with your cutting.

Limitations of Using a Utility Knife

While utility knives are versatile tools, there are limitations when it comes to cutting hardboard:

– Thickness: Utility knives may struggle with very thick sheets of hardboard. In such cases, using a saw (like a jigsaw or circular saw) may be more effective.

– Precision Cuts: For intricate designs or detailed cuts, specialized tools may yield better results.

Alternative Tools for Cutting Hardboard

If you find that using a utility knife is not yielding satisfactory results when trying to cut hardboard, consider these alternatives:

1. Jigsaw:

– A jigsaw equipped with a fine-toothed blade can easily cut through thicker hardboard while allowing for more intricate designs.

2. Circular Saw:

– For straight cuts on larger sheets of hardboard, a circular saw can make quick work of the material.

3. Table Saw:

– If you have access to one, a table saw provides precise cuts and is ideal for ripping large sheets down to size.

4. Hand Saw:

– A fine-toothed hand saw can also be used for cutting hardboard if power tools are not available.

Best Practices for Cutting Hardboard

To achieve the best results when cutting hardboard with any tool, consider these best practices:

1. Measure Twice, Cut Once:

– Always double-check your measurements before making cuts to avoid wasting material.

2. Use Sharp Blades:

– Ensure that your utility knife has a sharp blade; dull blades will require more force and can lead to uneven cuts.

3. Support Your Material:

– When cutting large sheets of hardboard, ensure they are adequately supported to prevent bending and snapping during the cut.

4. Practice on Scrap Material:

– If you’re new to cutting hardboard, practice on scrap pieces first to refine your technique.

5. Clean Up Edges:

– After cutting, use sandpaper or an edge trimmer to smooth any rough edges left behind.

The Role of Utility Knives in Manufacturing

As an essential tool in various industries, utility knives play a significant role in manufacturing processes:

– Versatility in Applications: Utility knives are used across industries for various tasks such as packaging, assembly, and fabrication.

– Cost-Effectiveness: They provide an economical solution for companies needing reliable cutting tools without investing in expensive machinery.

– Ease of Use: Utility knives are user-friendly and require minimal training, making them accessible for workers at all skill levels.

Insights from Nxtools: A Leading Utility Knife Factory

Nxtools specializes in producing high-quality utility knives designed for durability and performance. As a prominent utility knife factory, Nxtools focuses on:

– Quality Manufacturing Processes: Utilizing advanced technology and skilled craftsmanship ensures that each utility knife meets stringent quality standards.

– Innovative Designs: Continuous research and development lead to innovative designs that improve usability and safety features.

– Customer-Centric Approach: Nxtools prioritizes customer feedback to enhance product offerings and meet diverse market needs.

Conclusion

In conclusion, yes, you can cut hardboard with a utility knife using proper techniques such as scoring and making multiple passes. While utility knives are effective for thinner sheets of hardboard, thicker materials may require alternative tools for optimal results. By following best practices and understanding the limitations of your tools when trying to cut hardboard with a utility knife, you can achieve clean cuts and successful projects involving hardboard.

Frequently Asked Questions (FAQs)

1. Can I use any type of utility knife to cut hardboard?

– Yes, but using one with a sharp blade designed for heavy-duty tasks will yield better results when you cut hardboard with a utility knife.

2. What thickness of hardboard can I cut with a utility knife?

– A utility knife is most effective on sheets up to 1/8 inch thick; thicker sheets may require additional passes or different tools when trying to cut hardboard effectively.

3. What should I do if my utility knife blade becomes dull?

– Replace the blade promptly; using dull blades increases the risk of injury and produces poor cuts when attempting to cut hardboard.

4. Is it better to use power tools instead of a utility knife?

– For thicker materials or complex cuts involving hardboard, power tools like jigsaws or circular saws may be more efficient than manual cutting with a utility knife.

5. How do I ensure safety while cutting hardboard?

– Always wear gloves, keep your workspace clear, use sharp blades, and follow proper cutting techniques when attempting to cut hardboard with any tool.